PRODUCTION WORKSHOP

Quality Assurance

Production Workshop

Casting Workshop

The casting area is equipped with advanced melting and molding facilities, ensuring that each valve body is produced with high precision and structural strength. Strict inspection of raw materials and castings guarantees durability and reliability.

Here is the foundation of valve production. Equipped with advanced melting furnaces, sand molding systems, and automated pouring equipment, we produce valve bodies and key components with consistent quality. Raw materials are carefully selected and undergo strict chemical composition analysis before casting. Each casting is inspected using non-destructive testing (NDT) methods such as ultrasonic and radiographic testing to detect internal defects and guarantee structural integrity. This ensures that every valve body has the strength and durability required for high-pressure and demanding applications.

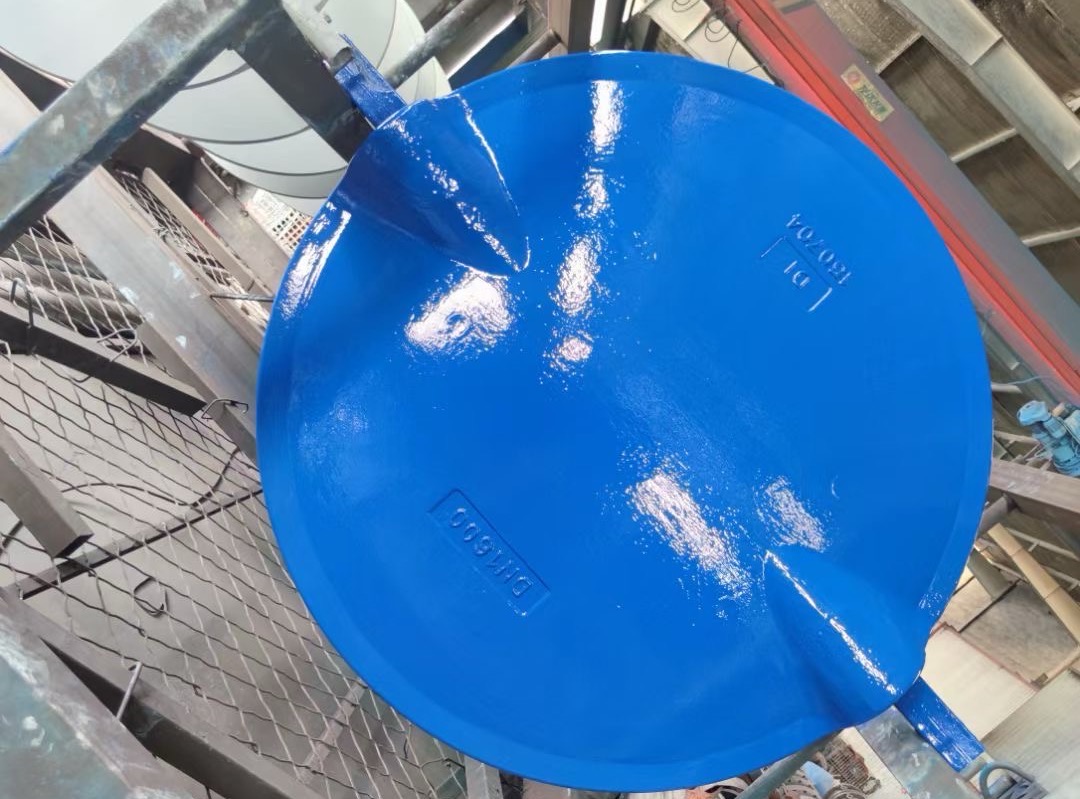

Coating Workshop

In the coating section, automated spraying and baking systems are applied to provide anti-corrosion protection and a smooth surface finish. This process enhances the valve’s resistance to harsh environments and extends its service life.

In the coating section, we adopt advanced surface treatment and spraying technology to protect valves against corrosion and wear. After thorough shot blasting and surface cleaning, valves are coated using automated spraying systems with epoxy, polyurethane, or special protective paints based on customer requirements. The coating is then cured through high-temperature baking, ensuring strong adhesion and long-lasting performance. This process not only enhances corrosion resistance but also provides a smooth, uniform finish that meets international environmental and safety standards.

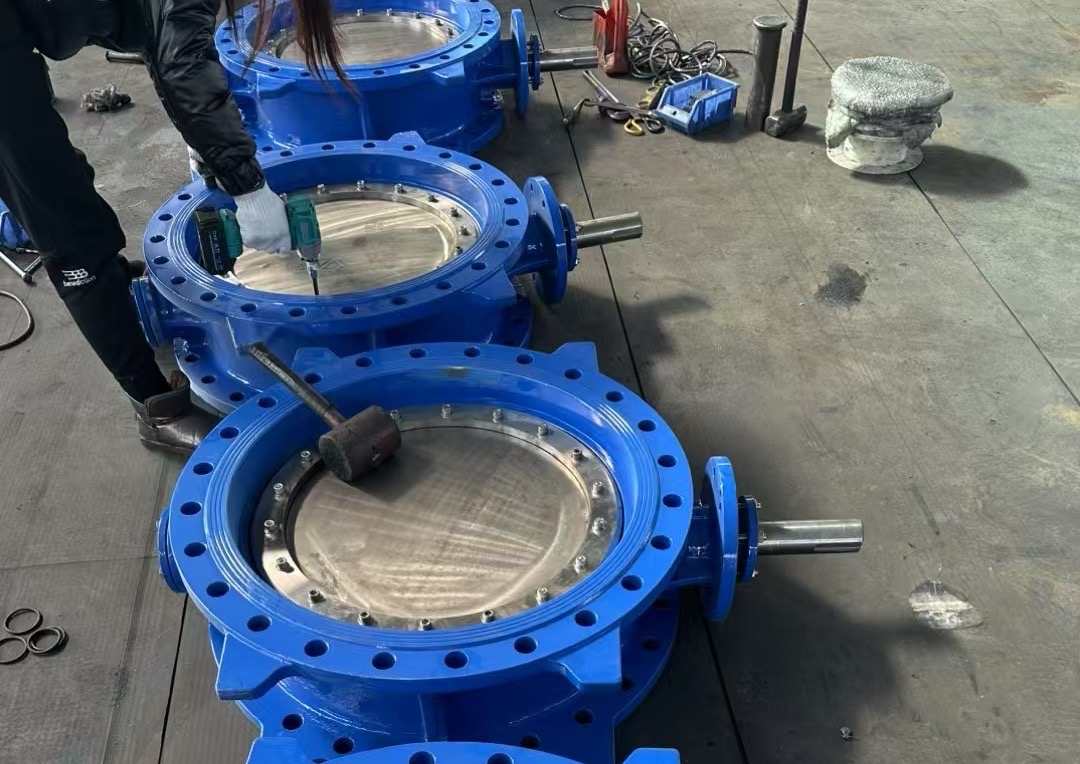

Assembly Workshop

The assembly line is managed by skilled technicians, combining precision machining components with strict quality checks. Each valve is carefully assembled, tested, and inspected to ensure optimal sealing performance and safe operation.

The assembly workshop is where precision engineering comes together. Skilled technicians assemble valve components—including bodies, discs, stems, and seats—under strict process controls. Advanced assembly lines and torque-controlled tools ensure accuracy and consistency. Each assembled valve is subjected to hydrostatic pressure testing, air-tightness testing, and functional checks to verify sealing performance and operational safety. Final inspections and detailed documentation ensure that only qualified products are released for delivery.