TESTING EQUIPMENT

Quality Assurance

Testing Equipment

Our valve factory follows strict testing and inspection procedures to ensure that every product meets international standards and customer requirements.

Pressure Testing

Each valve undergoes rigorous hydrostatic and air pressure testing in accordance with API, ISO, and other international standards. The hydrostatic test verifies the strength of the valve body under high pressure, while the air test checks for sealing performance and leakage. Valves are tested at pressures higher than their rated working pressure to ensure safety, durability, and reliability in real-world applications.

Quality Inspection

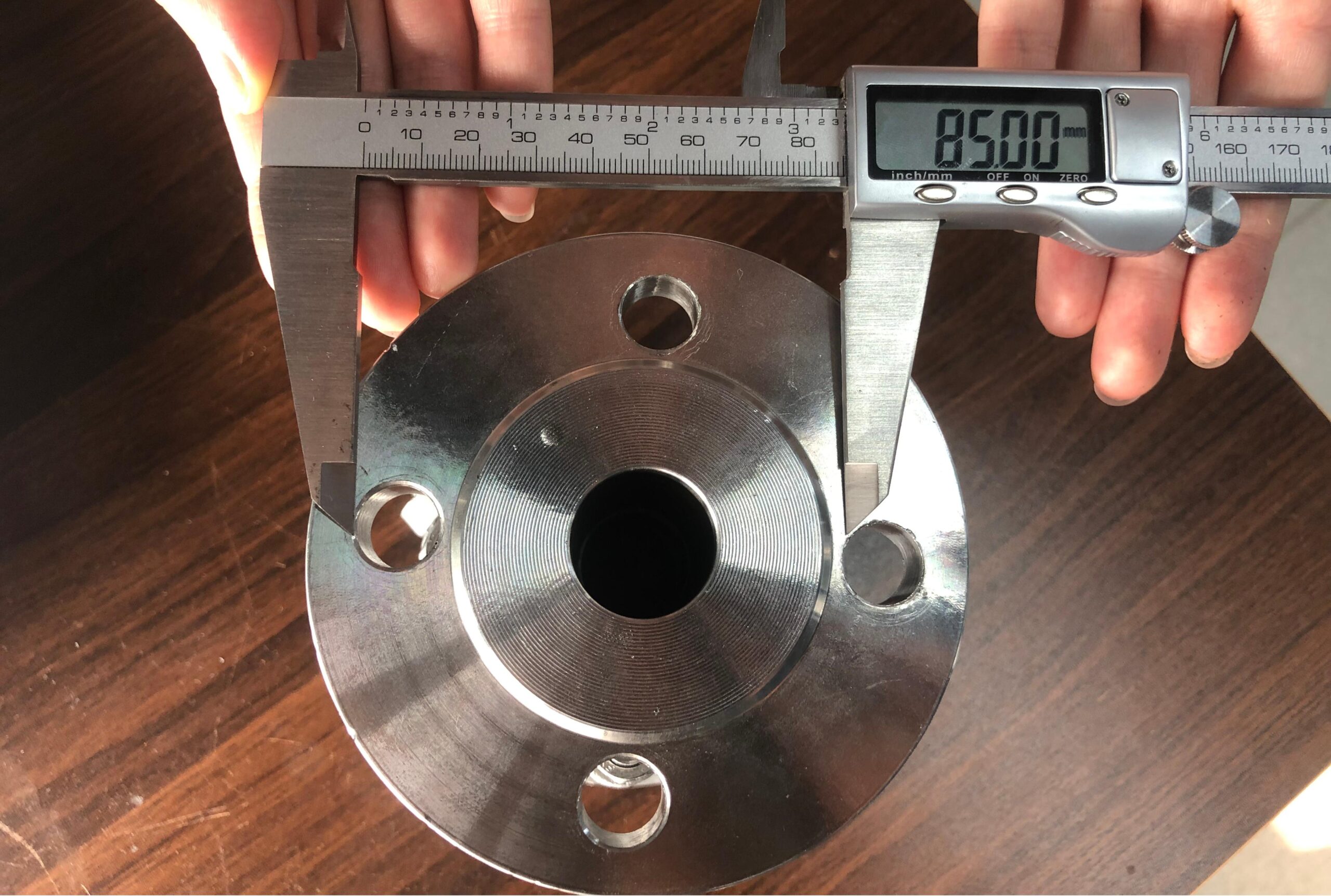

Quality inspection is conducted at multiple stages of production, from raw material verification to final product delivery. Non-destructive testing (NDT) methods such as ultrasonic, magnetic particle, and radiographic testing are applied to detect hidden defects in castings and machined parts. Dimensional inspections using precision instruments guarantee machining accuracy, while surface inspections ensure coating quality and corrosion resistance. Before shipment, each valve is subject to a final inspection report, ensuring complete traceability and compliance with customer specifications.